In an ideal world, continuous monitors would monitor continuously, but for some instruments downtime is necessary whilst service operations are undertaken. To overcome this,

Swan Analytical Instruments has developed a new technology for power and industrial water/steam monitoring systems to enable uninterrupted operation.

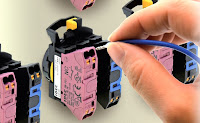

Chemists at the South Humber Bank Power Station (GB) have evaluated this innovative conductivity instrumentation, demonstrating its ability to avoid gaps in vital data streams, whilst also saving costs and lowering labour requirements. Swan’s AMI CACE (Conductivity After Cation Exchange), dispenses with the need to replenish the instrument’s cation exchange resin every month, which means that downtime is almost completely avoided.

After almost one year of uninterrupted operation with the AMI CACE, South Humber Bank Power Station Chemist Paul Kelk says: “CACE is a vitally important measurement because it amplifies conductivity readings so that we can measure the potential threat of corrosion. We have found this new Swan instrument to be extremely reliable, with a fast response time, and it has saved significant costs because it does not require manual resin replenishment every month. However, for me, the main advantage is that the instrument does not have to go off-line; as is the case with conventional resin-based CACE instruments.”

South Humber Bank Power Station

The South Humber Bank Power Station is a 1,365 MW combined cycle gas turbine (CCGT) power station, owned by EP UK Investments Ltd., a daughter company of EP Power Europe. The plant was built in two phases in 1997 and 1999. Phase 1 consists of three 166 MW gas turbines with three heat recovery steam generators, and a 255 MW steam turbine. Phase 2 consists of two 169 MW gas turbines with two heat recovery steam generators, and a 171 MW steam turbine. The plant operates once-through cooling using a deep-water intake drawn from about one mile into the River Humber estuary, at a rate of around 23m3 per second.

Why monitor conductivity?

Conductivity, in this context, is the non-specific ability of water in the water/steam cycle to carry an electrical current. This is made possible by the presence of dissolved substances – anions and cations, which may be treatment chemicals, dissolved gases or contaminants. The presence of these contaminants represents a threat to power station assets because of their ability to accumulate at points in the water/steam cycle and because they may cause corrosion in locations such as the main boiler, the steam turbine header, the condenser tubes and the hot well. Corrosion in these vital assets would necessitate remedial action, causing partial or complete plant shutdown with heavy financial consequences. Turbine blades would also be vulnerable to corrosion, and given that they travel at 3,000rpm, any damage could be catastrophic.

With the benefit of various conductivity measurements, South Humber Bank Power Station has been able to operate largely problem-free for many years. However, with an eye to the future, Paul Kelk says: “We are constantly on the lookout for new technologies that offer an opportunity to improve performance.”

Corrosion prevention

Corrosion occurs in the presence of water and oxygen, when metals revert to their oxidised, more stable state, so dissolved oxygen in cooling systems is avoided. Carbohydrazide is employed as a water treatment chemical at South Humber Bank Power Station. As a powerful oxygen scavenger Carbohydrazide promotes the formation of a protective magnetite layer without interfering with the action of other treatment chemicals. Magnetite is an iron oxide, (Fe3O4).which forms as a thin layer on steel surfaces and passivates them; thereby protecting the surfaces from corrosion.

Corrosion is an electrochemical process, and any build-up of dissolved contaminants could harm the magnetite layer and expose steel surfaces to the risk of corrosion. This risk is amplified where high pressure and temperature accelerate the corrosion process. So, the monitoring of conductivity provides the operators of steam cycle systems with early warning of potentially serious problems. However, contamination levels may be masked by the presence of alkalizing agents which have been added to protect the plant. For this reason, direct conductivity monitoring is undertaken, along with pH, as an indicator of treatment chemical levels.

In order to continuously monitor the potential threat from corrosive contaminants, it is necessary to remove the treatment chemicals from samples so that the underlying conductivity can be measured. This is achieved within the measurement instrument by passing the water sample through a cation exchange resin.

Conductivity after Cation Exchange (CACE)

|

| SWAN CACE Installed! |

In conventional CACE instruments a resin column changes contaminants into their acid form which amplifies the conductivity, allowing early detection of low level contaminants. Alkalizing agents can mask the contaminants as the column removes them from the sample by replacing them with protons in a cation exchange step before and after conductivity is measured. This process consumes resin and therefore necessitates regular resin replacement in order to assure reliable monitoring data.

Almost every power station monitors CACE to protect itself from the potentially serious effects of corrosion caused by contaminants in cycle steam/water. Paul Kelk says: “The main threats at this site are chloride and sulphide ions, so we employ fourteen CACE monitors with sampling points at both high and low pressure locations so that we can monitor any increase in levels, and take timely action to protect the plant.”

The frequency of resin replacement for conventional instruments depends on the type, quality and volume of the resin, as well as the pH, temperature and flow rate of the sample. Nuclear power plants, for example, running on a higher pH have an increased consumption of resin and need more frequent replacement or regeneration. At the South Humber plant, Paul estimates that each of the CACE monitors requires resin replacement once every 4 weeks. “We generally pre-prepare columns to speed up the process of swapping them. Once the column is taken from the instrument, the remaining resin is removed and discarded. The column is then washed with Hydrochloric Acid, which obviously presents safety challenges. Finally, the resin is replaced and the column is returned to the instrument, after which it is necessary to flush the column.”

The column exchange process takes around 20 minutes in total and has to be undertaken for each of the plant’s 14 CACE instruments every month. “In addition to the cost of the replacement resin and the avoidance of waste resin, the creation of replacement columns and the monthly swapping of columns, represents a significant ongoing labour requirement.” Paul explains. “However, the main problem is that resin column replacement causes the instrument readings to go off-scale for one to two hours, so we were obviously very interested to learn more about a new instrument that dispensed with the need for regular column replacement.”

CACE monitoring - without resin replacement

The innovative technology employed by Swan’s AMI CACE is electro-deionisation (EDI); a process in which the ion exchange resin is regenerated in place, continuously. Ions present in the feed-water pass through ion exchange membranes to a concentrate stream, and are thereby separated from the sample. The protons and hydroxide ions needed for regeneration are generated by water electrolysis, which eliminates the requirement for regeneration chemicals, and this means that it is possible to eliminate alkalizing agent up to specific conductivities of over 40 µS cm–1 in a single exchange step.

The AMI CACE measures conductivity both before and after cation exchange, and provides automatic calculation of pH and alkalizing agent concentration.

Monitoring at South Humber Bank Power Station

Samples are collected continuously from collection drums in the feedwater and condensate systems, and delivered to the plant’s analysers by a bespoke system that includes pressure reduction valves and cooling coils.

Manual samples are also collected routinely for laboratory analysis – to conduct a wider range of tests and to check that the online monitors are operating correctly.

In addition to the CACE monitors, SHBPC also operates continuous monitors for a range of other parameters including de-gassed conductivity, pH, phosphate, dissolved oxygen and hydrazine/carbohydrazide. Paul says: “Invariably, the initial purchase cost of Swan instruments is higher than other suppliers, but we believe in thorough, often lengthy, evaluation trials, and these have shown the operational costs of Swan equipment to be lower because of better reliability and a reduced maintenance requirement.

“We particularly appreciate Swan’s willingness to allow us to operate trial instruments for extended periods. This demonstrates confidence in their instruments and helps build a long-term relationship for the benefit of both parties.”

Continuous monitors should monitor continuously

The main advantage of continuous monitoring systems is that they are able to provide a complete picture of process conditions throughout a cycle, whilst also detecting sudden peaks so that alarms can be raised. It is therefore less than ideal when an analyser has to go offline for 1-2 hours every month for resin replacement. By developing an instrument that is able to remove this step, Swan has enabled true continuous monitoring of CACE at power plants.

In recent years, continuous monitoring systems with fast response times have become more important as power plants are required to respond more rapidly to changes in demand.

Summarising, John Saxton of Swan Analytical UK says: “Effective process control demands continuous analysis, so it was inevitable that the challenges of using traditional CACE instruments would need to be resolved, and we are obviously delighted that it was our company that developed the solution.

“Even without the operational cost savings, the case for replacing conventional CACE monitors with instruments employing EDI is overwhelming; given the enormous capital and strategic value of the assets that they protect.”

@_Enviro_News @swan_usa #PAuto #Power