An advanced test cell has been developed to monitor the functionality and performance of a compressor manufacturer’s compression boosters prior to dispatch. Humidity measurement represents a key element of the testing procedure and the company’s engineers have therefore deployed the latest Indigo-compatible, plug-and-play Vaisala humidity and temperature probe HMP4. Developed specifically for high pressure applications, the HMP4 is ideal for applications of this nature.

Vaisala’s Marc Mangelschots says: “The new Vaisala Indigo family takes industrial measurement to a new level, with interchangeable probes, smart transmitters and Indigo Insight PC software; helping users to streamline their processes and make more informed and timely decisions.”The boosters are compact, transportable diesel driven piston compressors that increase air pressure from a 25 bar input pressure to a 350 bar discharge pressure. The boosters are supplied to customers around the world in rental, service industry and well drilling applications. Their popularity is due to their transportability, reliability, ease of use, compact footprint, safety and efficiency.

Humidity is an important factor in the performance of compressors because the compression of atmospheric air causes the condensation of water in the compressed air line. Drying is therefore necessary, and the techniques for removing moisture from compressed air include cooling plus separation, over-compression, membranes, absorption and adsorption drying.

Explaining the role and importance of the humidity and temperature probes in the test cell, Marc says: “The HMP4 humidity probes are used to measure moisture content in both the suction and discharge air. This allows the operators to estimate the performance of the booster at different humidity levels and to evaluate the water separation efficiency of the water scrubbers on the booster. These measurements also enable estimation of the heat load on the booster coolers, which is derived from condensation during intercooling.

“The test cell therefore performs a vital role in ensuring the quality, reliability and performance of the boosters. This is especially important because our client’s customers frequently operate in remote locations where reliability and low maintenance requirements are essential.”

Designed to operate under high pressure, the Vaisala Humidity and Temperature Probe HMP4 is usually deployed in industrial applications involving high pressures and where measurement performance and stability are essential. In common with Vaisala’s other humidity sensors, the HMP4 sensor offers a number of major advantages including long-term stability and insensitivity to condensation, dirt and most chemicals.

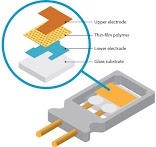

The probe employs Vaisala’s HUMICAP® technology, which is a capacitive thin-film polymer sensor consisting of a substrate with a thin film of polymer deposited between two conductive electrodes, which electrically forms a capacitor. The sensing surface is coated with a porous metal electrode to allowing the humidity to freely move into the active polymer. The thin-film polymer either absorbs or releases water vapor as the relative humidity changes, and this alters the dielectric properties of the polymer film and thereby the capacitance of the sensor, which is converted into a humidity reading. Humidity measurement accuracy is ±0.8%RH, and temperature accuracy is ±0.1 °C.

Vaisala is the original innovator of the thin-film capacitive humidity measurement technology, which has become the industry standard in humidity measurement. In fact, this Vaisala technology has been employed by a variety of space agencies. NASA, for example, used it on missions to Mars, and famously in 2015, enabled the Mars Science Laboratory, the Curiosity rover, to find the first traces of ancient water on Mars.

The HMP4 is one of Vaisala’s latest smart, plug-and-play probes, and is compatible with the Indigo series of transmitters. Conveniently, for field calibration, device analytics, and configuration functionality, the probe can be connected directly to a PC through Vaisala Insight PC Software.

The HMP4 probe can be used as a stand-alone measurement instrument through the Modbus RTU interface. However, the test cell has been fitted with the Vaisala Indigo520 Transmitter. Marc says: “In this application the most important feature of the Indigo520 transmitter is the digital communication that is used to send data to our automated data acquisition system.

“The accuracy and reliability of the sensors is of paramount importance, but particularly useful additional feature of the probes is their LED-indicator (green/red/blinking) which allows for easy troubleshooting during test cell start-up.”

@VaisalaGroup @_Enviro_News #Manufacturing #Pauto

No comments:

Post a Comment